Fine bubbles are used for cleaning and sterilization of industrial products and foods.

Fine bubbles are negatively charged and gather positive (+) substances. The cleaning power is enhanced by several effects fine bubbles have such as; the effect of degreasing, the effect of peeling off deposits by entering between the deposits and the cleaning object, and the force and shock waves when the bubbles burst.

One of the great effect of fine bubbles is a very high detergency. This cleaning mechanism is considered to be as follows.

In the cleaning of contaminants adhering to the surface of silicon wafers, when using an ultrapure water jet containing UFB (ultra-fine-bubbles / nanobubbles), the force and shock waves at the time of bubbles burst dramatically enhance the cleaning power.

Fine bubbles have a degreasing effect of separating and removing the oil as they permeate the oil and permeate between the boundary with the adhering surface. Also, it can penetrate into the narrow space between the objects that are in close contact with each other, and as the nano-sized bubbles coalesce into microbubbles, which can act as wedges to separate them. These characteristics enhances detergency. This can be used for numerous solutions and is currently used for home baths / showers, dishwashing, and cleaning of machine parts.

It also has a high sterilization effect. Not only the bacteria attached to the surface, but also the fine bubbles permeate the body of the shrimp and sterilize them, and nearly 90% of the bacteria have been successfully sterilized with the fine bubbles using tap water and atmospheric air.

Cleaning experiment

The result of cleaning silicon wafer using ultra-fine-bubbles

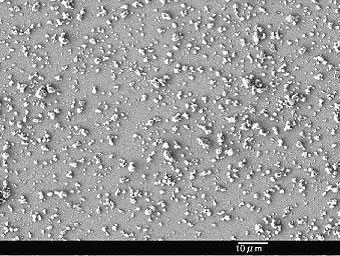

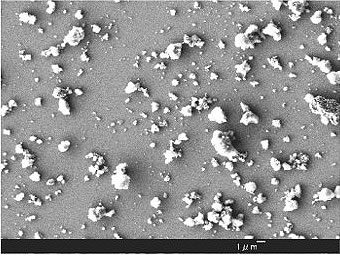

After ultra-pure water jet cleaning

1000 magnification |

3000 magnification |

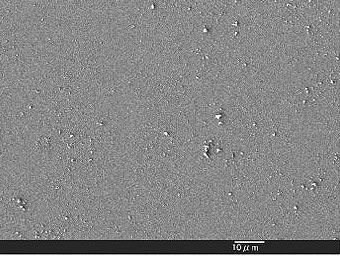

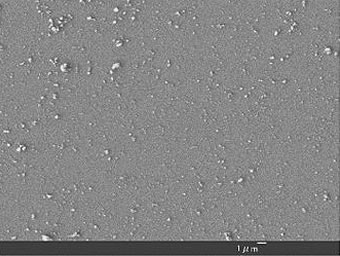

After ultra-pure water + ultra-fine-bubble jet cleaning

1000 magnification |

3000 magnification |

Effect of cleaning

| Before cleaning | After ultra-pure water cleaning | After ultra-pure water + ultra-fine-bubble jet cleaning | ||

| picture of 1000 magnification | picture of 3000 magnification | |||

| Square measure | 359~472um2 | 320~482um2 | 28.65um2 | 37.33um2 |

| Cleaning rate due to UFB : 92. 13% as area ratio | ||||

Experimentally verified the effect of removing fine particles on the solid surface by pressure waves, utilizing the characteristic that the inside of ultra-fine-bubbles become high pressure.

It became clear that the fine particles over 1 micron were removed and no longer observed, and the ratio of the area that could be washed reached 92%.

Mechanism of cleaning silicon wafer(PDF)

Application examples related to cleaning & sterilization

Using fine bubbles for super-clear mirror surface polishing of silicon wafer

Easily achieved the required mirror surface!!

● Fine bubbles were used to solve the problem because even though several types of measures were taken, the required super-clear mirror surface could not be achieved.

● Fine bubbles were used to solve the problem because even though several types of measures were taken, the required super-clear mirror surface could not be achieved.

● OK nozzles are installed in the middle of the grinding fluid piping.

● We received words of gratitude from this company saying, “We are very pleased to be able to supply accepted products.”

● The cutting edge of the grindstone was always secured by the impact of the burst of the fine bubbles, and also the ground cutting chips were cleaned to obtain the required surface quality.

Vegetable cleaning in England

1) 7 L/min OK Nozzles x 10 for potato washing machine

Fine bubbles are used for washing soil and sand from potato eyes.

|

|

2) 100 L/min OK Nozzles x 3 for a large potato washing machine

Since the potato washing with ten 7 L/min units worked so well, three of 100 L/min units was adopted for a larger potato washing machine.

3) 300 L/min OK Nozzle for leaf vegetable washing

Since using fine bubbles was so effective for the potato washing, the same company started using 300 L/min OK Nozzle for the leaf vegetable washing machine.