Air and oxygen fine bubbles are used for the improvement of the quality of water in the sea, rivers, lakes and ponds.

Water quality can be improved by increasing the dissolved oxygen concentration with fine bubbles and activating microorganisms with ultra fine bubbles.

Main achievements related to microbial activation and water purification

● Water purification — Rivers, lakes, ponds, water tanks, fish preserves, pools

● Wastewater treatment — Approx. 50% power saving of aeration.

There are cases that sludge is hardly produced when oxygen is self-absorbed. Significant reduction in sludge disposal costs is possible.

● Sewage treatment — Experiment started in September 2015

● Excreta treatment of livestock such as pigs

Main application examples related to microbial activation and water purification

Paint booth water tank purification using 100L/min OK Nozzle

|

With fine bubbles |

Without fine bubbles |

Fine Bubble Generation inside the Painting Booth Tank

Moat water of Yodo castle purification experiment

1. Experiment purpose

Before purifying the water of Yodo-castle moat directly on the spot, we conducted a purification experiment in a water tank for the purpose of determining the effects of fine bubbles. Visual observations, camera photographs and microscope observational photographs were used as the methods to determine the purification.

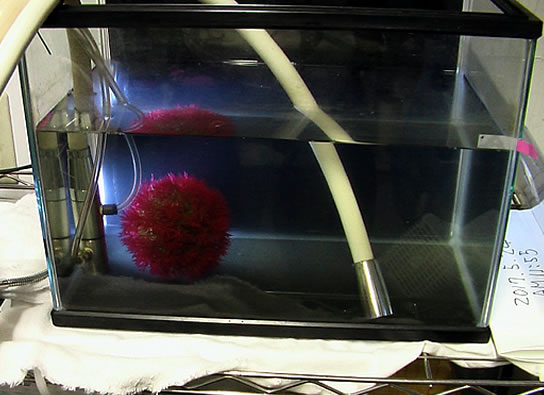

2. Experiment apparatus

Fine bubble generating experiment apparatus was composed from the devices below.

a) Loop Flow OK Nozzle: OKE-MB07FJ(20 L/min)

b) Water tank: 10L(Acrylic transparent)

c) Pump: MD70RZM(IWAKI product)

d) Gas flow meter: MF-F (HORIBA product)

e) Pressure gauge: Max 0.4MPa f) Bio-carrier : Flexible resin needle ball (Φ79)

3. Experiment method

(1) Put approx. 7L of raw water from the moat into the 10L water tank and generate fine bubbles using a loop flow OK Nozzle.

Experimental condition is:

a) Water pressure: 0.06MPa

b) Air intake: 35mL/min

As the water amount was 7L, the condition was lowered.

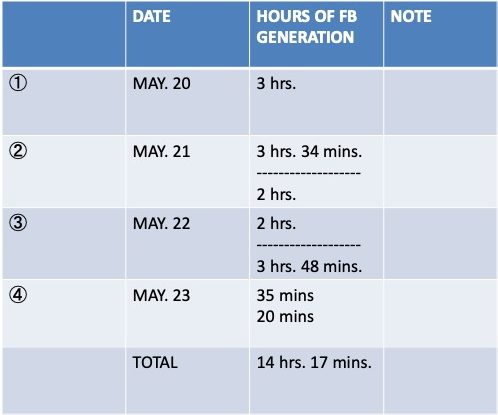

(2) The fine bubbles were generated for some hours not continuously but with intervals. It was not operated at night time because the water temperature rises a lot when operated for a long time. Operating times are written below.

4. Experiment results (excerpt)

(1) The times of fine bubble generation

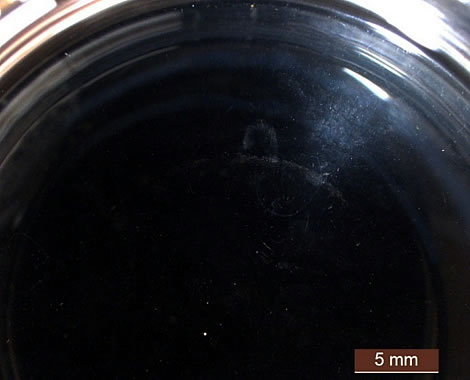

(2) Photograph determination

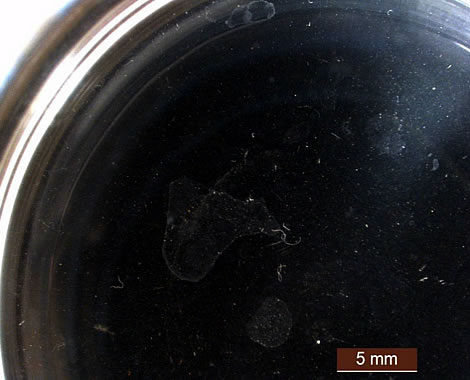

Higher transparency after the fine bubble purification.

|

a. May. 20 (Raw water before FB operation)) |

b. May. 25 (After FB purification) |

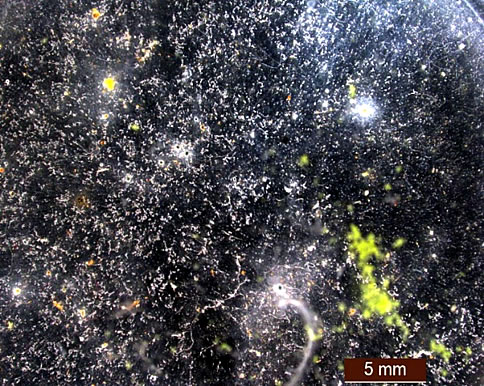

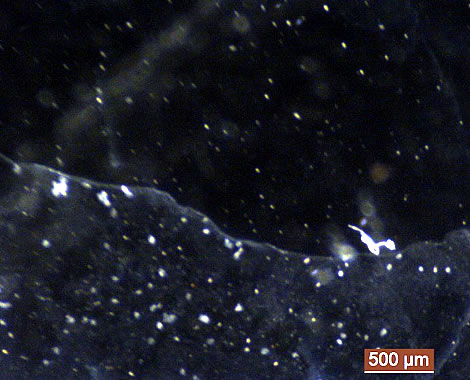

(3) Microscope photograph

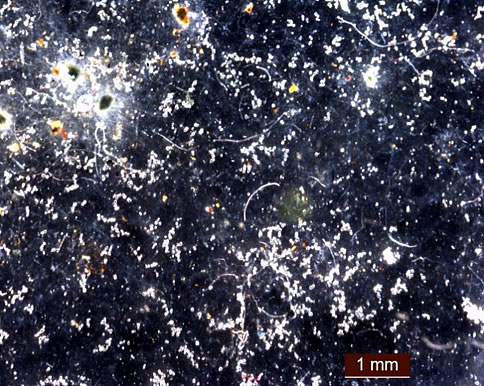

a. Raw water (Supernatant in a polyethylene tank) shot on May. 24

|

|

|

|

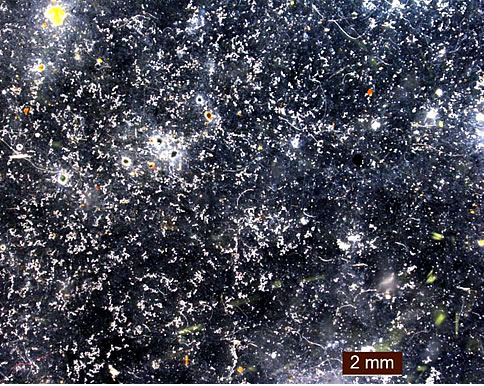

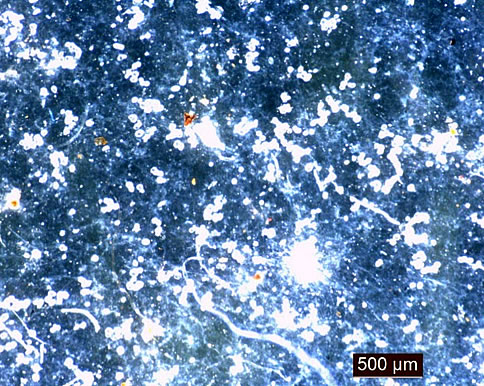

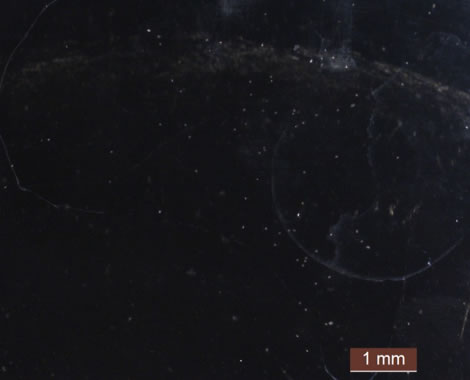

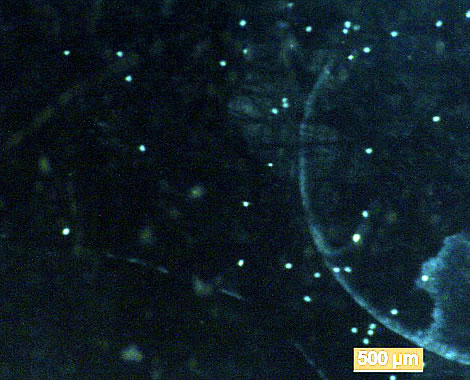

(4) Water after the fine bubble purification

a. 2017. May. 24 (First day of stopping FB generation)

|

|

|

|

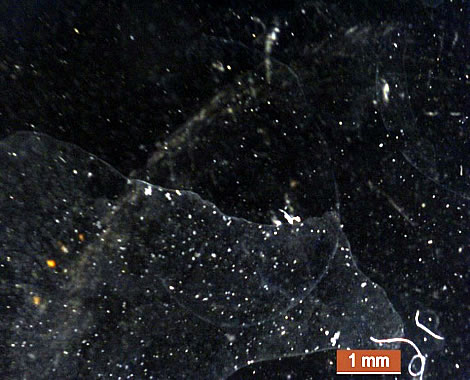

b. May. 26 (Third day after stopping FB generation)

|

|

|

|

5. Examination

a. As can be seen from the experiment photos of water tank and the microscope photos, contaminations inside the water are removed by generating fine bubbles. This is inferred that the microorganisms in the water were activated by fine bubbles and thus purified the water.

b. When we observed the raw water and the purified water by putting them into a 100ml beaker and held it up to the light;

– In the raw water, a lot of small supernatants were seen.

– In the purified water, no contaminations were checked visually.

c. After generating fine bubbles until May. 23rd, we observed how the purified water had changed with microscope. Compared to the microscope photos of the 24th and 25th, there were almost no contaminations in the photos taken on the 26th. This is inferred to be a result of the precipitation of the contaminations and the microbial function.

d. From these experiment results, it was proved that the loop flow fine bubble generation OK Nozzle exhibits high effect for purifying moat water of Yodo castle.

Wastewater treatment with 500 L/min OK Nozzle

Building underground wastewater treatment plant in Umeda, Osaka. (Hankyu Department Building)

The problem they had in the underground plant was solved by installing an OK Nozzle in the second tank.

|

|

- The first tank had a nanobubble nozzle from another company but it did not work well, and the DO was 0 ppm.

- After installing OK Nozzle in the second tank, DO in the third tank increased to 4 ppm.

- As well as DO, adding fine bubbles increases processing capacity due to microbial activation.

Connecting 500 L/min OK Nozzle to a submersible pump and fix them in a filtration cage.

Filtration (wire mesh) cage is important to prevent contaminants from clogging the nozzle and the pump.