The result of cleaning with ultra fine bubbles

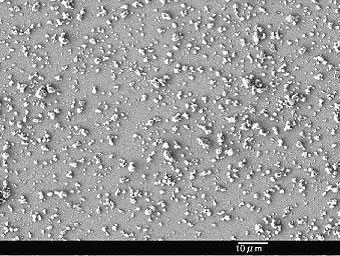

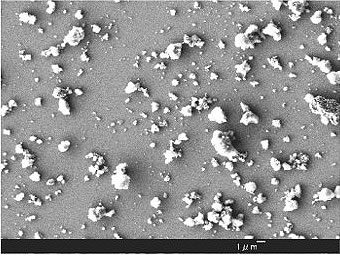

After ultra pure water cleaning

1000 magnification |

3000 magnification |

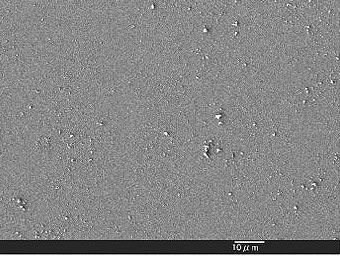

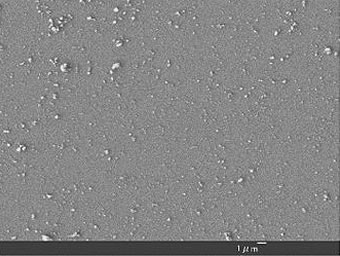

After ultra pure water + ultra fine bubble cleaning

1000 magnification |

3000 magnification |

Results of cleaning

| After cleaning | After ultra pure water cleaning | After ultra pure water jet + ultra fine bubble cleaning | ||

| picture of 1000 magnification | picture of 3000 magnification | |||

| Square measure | 359~472um2 | 320~482um2 | 28.65um2 | 37.33um2 |

| Cleaning rate due to ultra fine bubbles : 92.13% as area ratio | ||||

Experimentally validated the effect of removing particles on the solid surface by pressure waves, utilizing the characteristics of high pressure inside the ultra-fine-bubbles.

It became clear that particles above 1 micron were removed and no longer observed, and that the area percentage that could be washed reaches 92%.